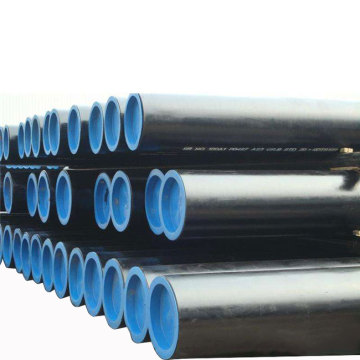

X60 material apI 5L 8 spiral welded pipe

Basic Info

Model No.: Outer Diameter(Round):60~1420mm Thickness:2.5~3.7mm

Product Description

X60 material apI 5L 8 spiral welded Pipe

Hebei Chengyuan Pipe Industry Group Co., Ltd.

X60 material apI 5L 8 spiral welded pipe customization submerged arc welding process

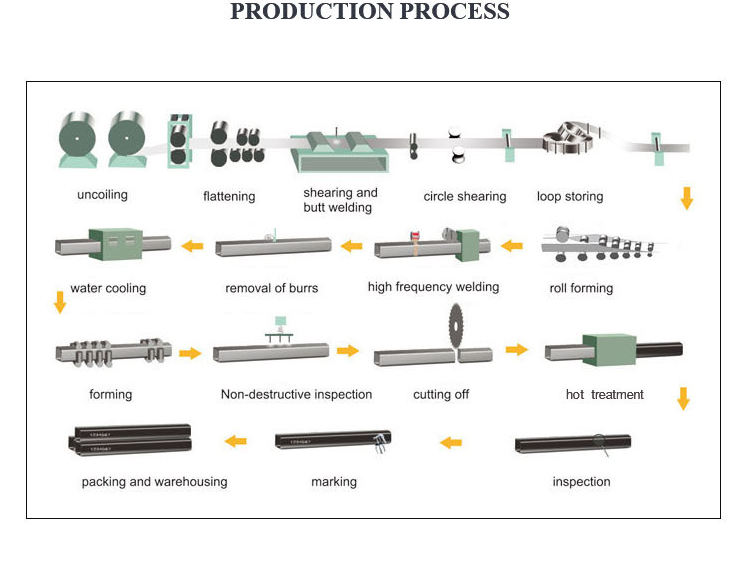

1. Plate penetration: after the steel plate used to make large-diameter submerged arc welding straight seam steel pipe enters the production line, it shall first carry out full-plate ultrasonic inspection;

2. Edge milling: double milling the two edges of the steel plate through the edge milling machine to achieve the required width, parallelism of the edge and groove shape;

3. Pre-bending: pre-bending is carried out by using the pre-bending machine to make the plate edge have the required curvature;

4. Molding: in the JCO molding machine, first, half of the prebent steel plate is pressed into the "J" shape through several steps, and then the Other half of the steel plate is also bent, forming the "C" shape, and the # is then formed into the open "O" shape.

5. Pre-welding: make the straight welded steel pipe joint after forming and use gas shielded welding (MAG) for continuous welding;

6. Internal welding: adopt longitudinal multi-wire submerged arc welding (# can be more than 4 wires) to weld inside straight steel pipe;

7. External welding: adopt longitudinal multi-wire submerged arc welding to weld on the outside of vertical submerged arc welding steel pipe.Now the HRB Φ - mm executive yuan / *.

8. Ultrasonic inspection Ⅰ: inside and outside of straight seam welded steel pipe weld and weld on both sides of the base of 100% of the check;

9. X-ray Ⅰ: 100% of inside and outside weld X-ray industrial TV inspection, using image processing system to ensure the sensitivity of detection;

10. Diameter expanding: the full length of straight pipe of submerged arc welding is enlarged to improve the dimensional accuracy of the pipe and the distribution of internal stress of the pipe.

11. Water pressure test: the enlarged steel pipe is inspected one by one on the water pressure test machine to ensure that the steel pipe meets the standard pressure. The machine has the function of automatic recording and storage.

12. Chamfering: finish the pipe end after passing the inspection, and reach the required size of pipe end groove.

13. The ultrasonic inspection Ⅱ: root by ultrasonic inspection to check again after the straight seam welded steel pipe in the hole diameter, water pressure may produce defects.

14. X-ray Ⅱ: for hole enlargement and after water pressure test of tube X-ray industrial TV inspection and pipe weld filmmaking.

15. Magnetic powder inspection of tube end: this inspection is carried out to discover the defect of tube end;

16. Corrosion protection and coating: qualified steel pipe shall be corroded and coated according to user requirements.

Product Categories : Spiral Steel Pipe